Storelectric is participating fully in the hydrogen economy in six ways:

- Hydrogen CAES

- Hydrogen storage

- CAES and Hydrogen Projects

- Integrated Projects

- High-temperature hydrogen patent

- Consultations

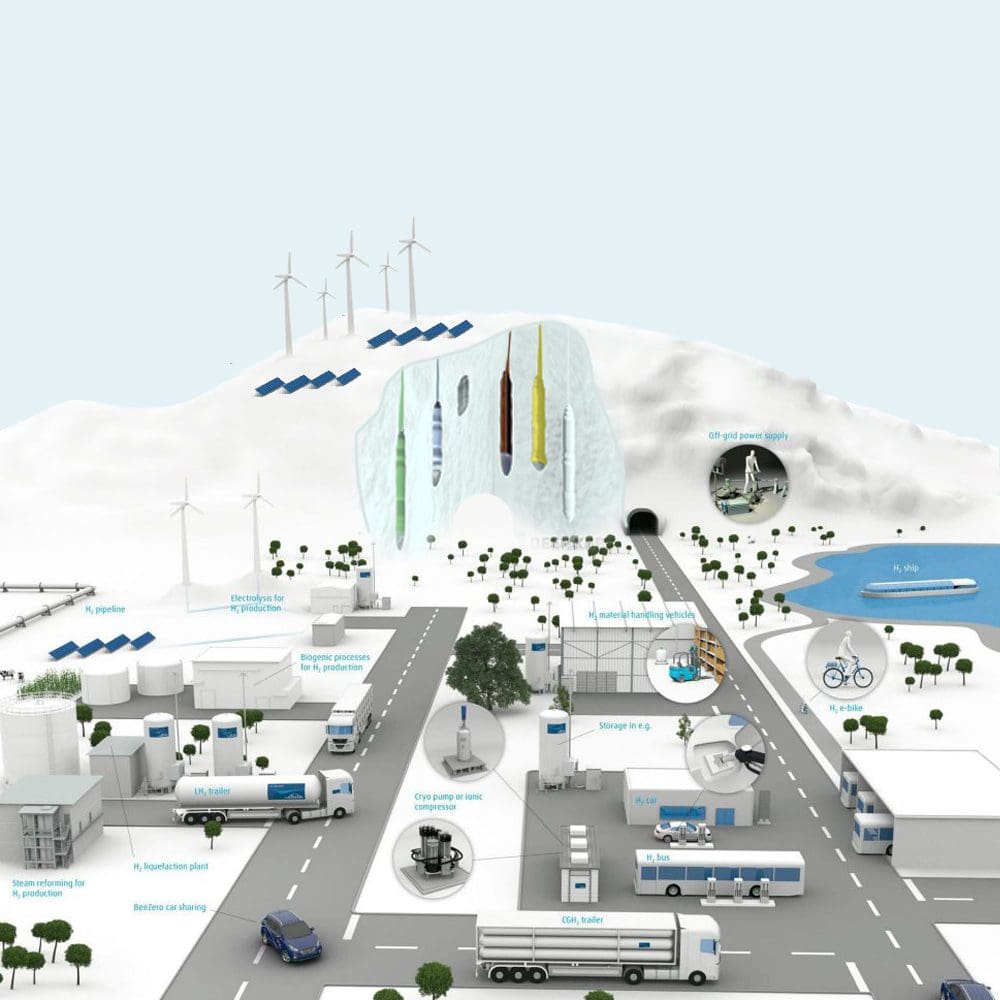

We expect future energy networks to be like today’s networks with two major elements: hydrogen and electricity; today, they are methane and electricity. With investment, methane grids can be converted to hydrogen grids; much of recent years’ grid investments in recent years in many countries has been hydrogen compatible. Of course, electricity is needed to make the hydrogen, and hydrogen in turn will be used to make synthetic fuels, but what is transmitted along networks will mainly be these two. As with today’s gas and electricity grids, they are mutually complementary, compete little with each other and, again as at present, some applications use both.

The part that hydrogen will play in the energy transition is huge, focusing primarily on the gas grid, industrial processes (e.g. iron and steel making), heating, transportation, synthetic fuels and catalysing other processes such as CAES. So most hydrogen solutions must be at the same scale as the gas plants and equipment that they replace.

Hydrogen CAES

Storelectric’s Hydrogen CAES is hydrogen ready. Until sufficient hydrogen is available at suitable prices, it can burn methane or any mix of hydrogen and methane. Thus it will decarbonise as the energy transition progresses. The hydrogen could be obtained either from the gas grid (which many countries will convert to hydrogen and, sooner, mixes of hydrogen and methane) or dedicated production on-site or near-site.

Hydrogen Storage

An average 40-ft tank at 20bar pressure carries only 75kg of hydrogen. So massive-scale Hydrogen storage is required. Salt caverns can store hydrogen at such scale, tens of millions of times larger and at pressures better suited to both the output of electrolysis and the needs of the grid. Indeed, these caverns are very similar to those used for CAES, and adjacent to them, though with higher-grade materials in their drill strings, wellheads and other pipework and sundries.

Those designed for hydrogen can carry air, but not necessarily vice-versa. Storelectric plans to have hydrogen caverns adjacent to its air caverns, and to have at least some air caverns built to hydrogen standards for future convertibility. This also leaves us well-placed to provide large-scale storage for leasing to other companies’ hydrogen projects.

CAES and Hydrogen

There are other synergies between CAES and hydrogen, especially because electrolysis does not operate as efficiently when powered intermittently. By including CAES in a renewables + hydrogen project, we can deliver near-baseload energy to the electrolysers, as well as high-value services to the electricity grid, and can do so very cost-effectively.

Not only is it more efficient when operating as near-baseload, but it also requires much fewer electrolysers per unit of output hydrogen, greatly reducing capital costs and somewhat reducing operational costs. Thus CAES acts as both a provider to the grid and a project-and-performance enhancer to the hydrogen.

Integrated Projects

Storelectric’s CAES (electricity storage) and hydrogen are ideal jointly as inputs to many other processes that need both to be delivered concurrently. These include:

- Renewable generation of almost any type, including mixed, at large scale;

- Fuel and chemical synthesis, e.g. ammonia (NH3) and methanol (CH3OH), both of which are both fuels and feedstock into other processes –

- The CAES plant can also support nitrogen and carbon extraction processes;

- Iron and steel making, where hydrogen replaces coal for both heat and chemical reduction processes;

- Synthesis of other hydrocarbons;

- Other industrial and chemical processes.

Indeed, the more integrated the project is, the more efficient and cost-effective the resultant plant can be. And such projects can use many proven technologies from suppliers of complementary systems.

High-Temperature Hydrogen Patent

Breaking water into hydrogen and oxygen takes energy, and the more of that energy that comes from heat, the less is required from electricity. Storelectric has a granted patent (PCT/GB2019/052168) in using the heat of compression to catalyse electrolysis. This has the potential to provide large amounts of very cost-effective green hydrogen for the hydrogen economy, which could be a game-changer due to the cost of electrolysing hydrogen today.

Learn more about our Hydrogen Technology.

This patent has been granted and, within the above description, is relatively broad and strong. But it needs a few years’ R&D to turn it into a commercial reality. We intend to use the proceeds of CAES plants, and/or investment, to finance this work.

Consultations

With all this evident expertise, Storelectric is increasingly being consulted for other projects involving hydrogen and its storage, including optimising complex systems that involve many linked processes, which may or may not involve CAES.