Large-scale, long-duration

ElECTRICITY Storage

Many nations have the potential to be energy-independent through renewable energy and electricity storage. However, the missing piece of the energy puzzle is storing that renewable energy at GWh and TWh scale; dispatchable at any time, in any season.

Storelectric’s adiabatic Green CAES™ is an efficient, cost-effective electricity storage solution. Widely implementable and with zero emissions, it has the potential to solve the energy storage problem.

CAES: A proven technology, improved.

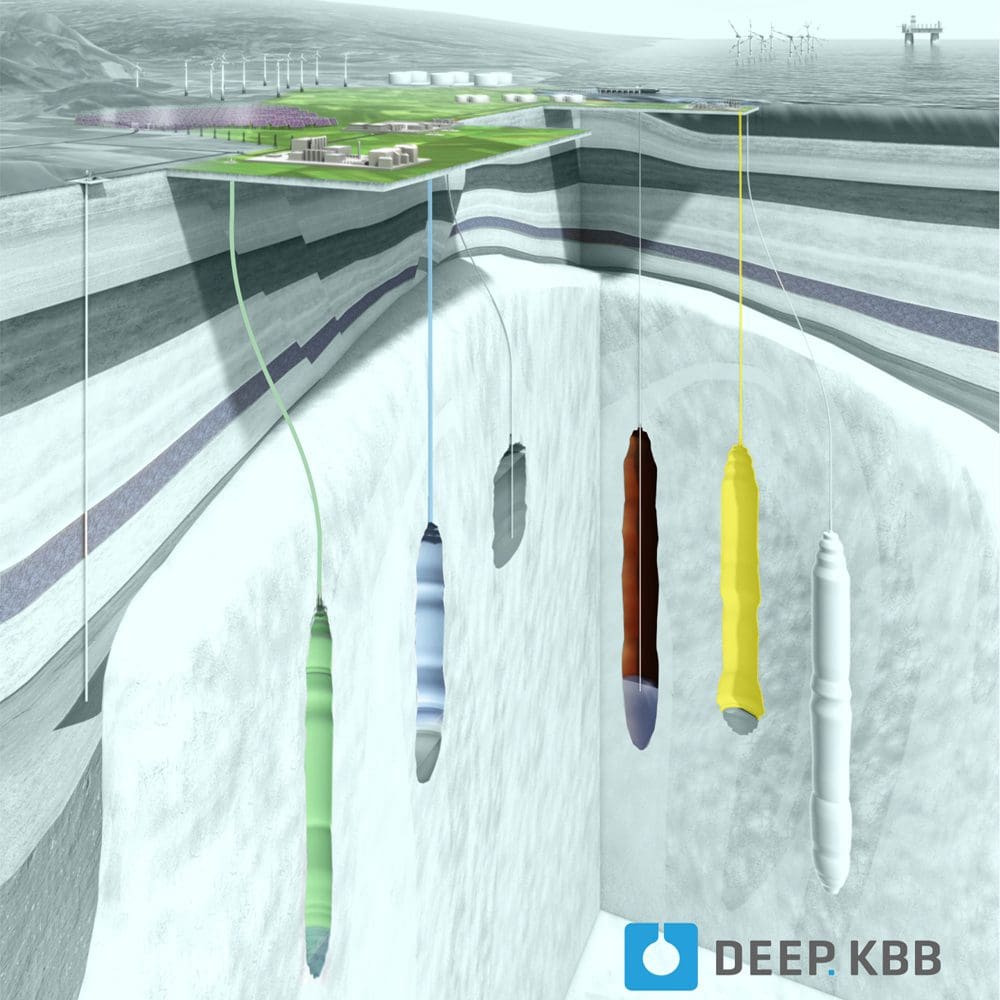

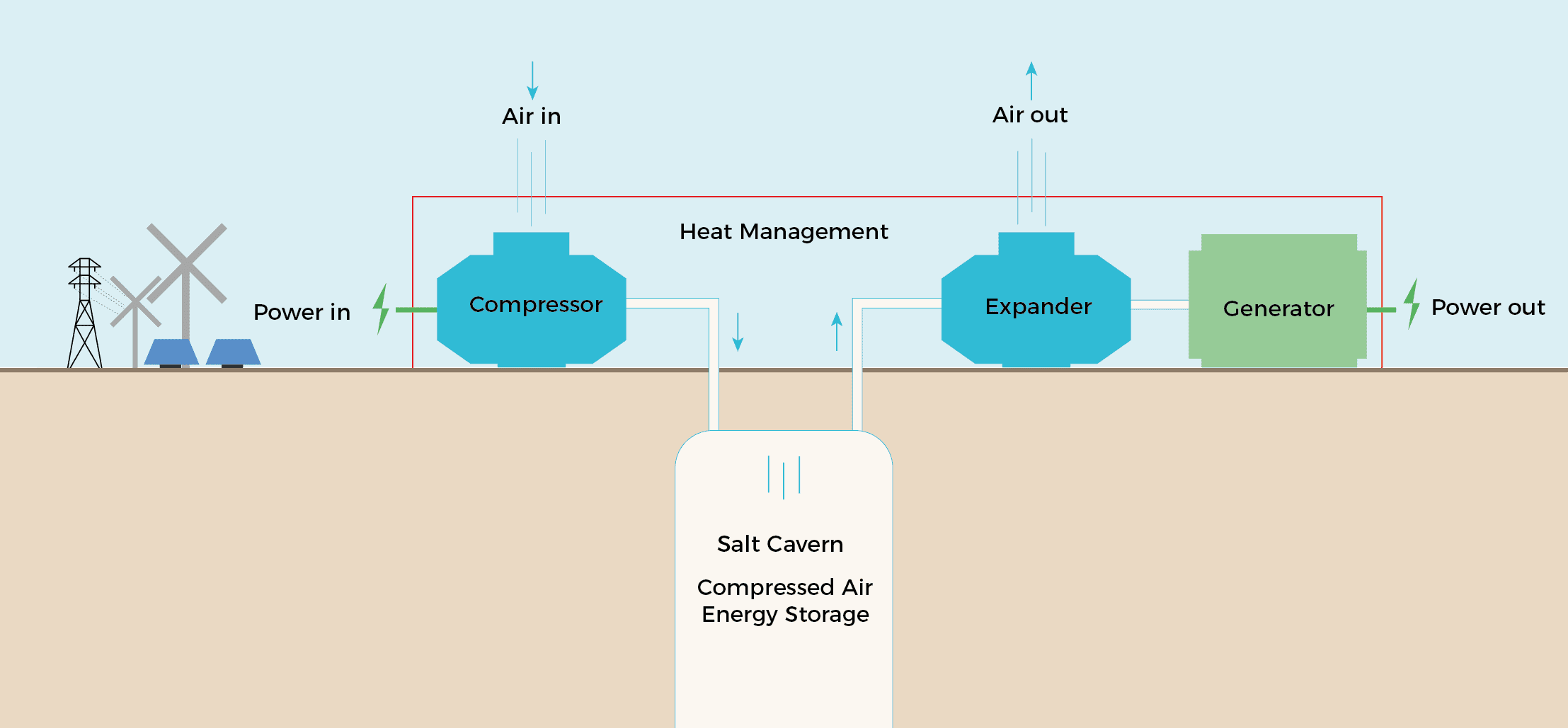

All CAES systems use surplus low-price electricity to pressurise air, which is stored in underground salt caverns. When needed, the air is released to regenerate electricity.

The technology has been proven; CAES has been in operation since 1978 in Huntorf in Germany, and since 1991 in McIntosh, Alabama, USA.

However, these systems regenerate electricity by feeding it into a gas-fired power station, burning and polluting about 60–70% as much as a gas-fired power station.

GREEN CAES™

Our green CAES™ technology uses a thermal energy management & storage system to recover lost heat from the compression process and reuse it in the power cycle.

Not only does it do so considerably more efficiently than other adiabatic CAES technologies, but it can also uniquely be built from readily-available equipment from multiple suppliers, and is therefore cheaper, more reliable, operates at a much wider range of cavern pressures (i.e. can be built in many more locations), and more configurable to optimise for different uses.

Green CAES is a simplification of the Huntorf plant, replacing Huntorf’s gas feed, combustion, cooling tower, smoke stack and emissions abatement (“scrubbing”) equipment with simple thermal storage.

HYDROGEN CAES™

Our Hydrogen CAESTM (also known as H2 CAESTM) technology uses a different configuration of existing equipment to increase the efficiency of traditional CAES by 10–15% while reducing its costs by over 40% and making it hydrogen-ready.

The plants can burn natural gas, hydrogen or any mix of the two. As the gas grid decarbonises, so these plants will decarbonise. This is the cheapest large-scale electricity storage technology, a simplification of the McIntosh plant.

HYDROGEN HYBRID™

Our Hydrogen hybridTM technology adds thermal storage and management to our H2 CAES, providing a further 15–20% uplift in efficiency.

When burning methane or a mix, it also provides a similar reduction in total emissions.

compressed air energy storge

how it works

1.

Renewable energy or excess energy from the grid is used to drive air through a compressor.

2.

The pressurised air is stored in underground salt caverns until there is demand for electricity.

3.

When required, the air is delivered back to the surface where it is heated and expanded.

4.

The expanded air is sent through a turbine, driving a generator and producing power.

UNRIVALLED ENERGY STORAGE

Our adiabatic Green CAESTM solution uses significantly fewer resources in setup and operation than batteries. It has a longer life, better efficiency (measured whole-life, grid-to-grid), is far more cost effective, and has more available geographical locations than pumped hydro, and has far greater efficiencies than any other existing CAES solutions.

Zero or low emissions

Operational configurations include emission-free option and fossil fuel option with a greatly reduced carbon footprint.

Grid Scale, Long duration storage

40MW to multi-GW, 4-hour to multi-day duration storage tackles the renewable energy intermittency dilemma.

built to last

30+ years with little efficiency loss on mechanical and up to 100 years on underground caverns — and counting!

highly efficient

Independently verified to achieve high efficiencies:

Green CAES ™ 62%–70%;

Hydrogen CAES™ 50%–>60% depending on plant size.

asset repurposing

We build new, or re-purpose salt caverns, mines and power stations, resulting in lower financial and environmental costs with added revenue streams.

proven yet unique

Based on a proven CAES system but improved upon with a simpler and more compact arrangement, greater efficiencies and lower CAPEX costs.

“

“If we find ways of generating AND STORING power from renewable resources, we will make the problem…disappear.”

— DAVID ATTENBOROUGH

(Interview with Barack Obama)

WHY STORELECTRIC?

- A short plant life

- Too-low lifetime-average grid-to-grid efficiency

- Lack of real inertia

- Inability to deliver other services at the same time with the same capacity

- Resource scarcity for manufacture

- Difficulty and high cost in end-of-life recycling

- Small size and limited capacity make them suitable for only smaller-scale work

Batteries can be set up to deliver only one of balancing, stability, operability, resilience and grid congestion reduction services, each of which our plants can deliver concurrently (batteries cannot provide Black Start to other / higher-voltage grid sections, and their stability services are based on much-inferior “synthetic inertia”).

Our plants are much cheaper and more efficient (lifetime average, grid-to-grid) than batteries, with 5X their plant life, and each of our plants can concurrently deliver a range of services that would require 4–6 of the same-sized batteries.

As reliance on renewables increases, the challenges of managing the grid start to rise exponentially.

Once renewables account for over ~16% of electricity in the grid, based on the British experience, the non-energy costs of running the grid increase exponentially, in each of the three main categories:

- ¼ balancing costs, ensuring that there is sufficient energy at any given time;

- ¼ grid stability and operability costs, ensuring the smooth running of the grid;

- ½ grid reinforcement costs; building more grid to accommodate intermittency (analysts forecast that it would have to more than triple in size) and connecting additional plants for balancing, stability, operability and related services.

In 2022–23 these costs were over 14X more expensive than just 3 years before (see blog for more: Challenges of the Electricity Transition).

Storelectric’s plants, suitably located, address all of these issues with unrivalled cost-effectiveness and low technical risk.

Our CAES plants are low-risk simplifications of existing plants that have run for decades, using off-the-shelf equipment well proven in power generation & other industries. Green CAES has been validated by Costain, Arup, Mott MacDonald, Fortum, Mitsubishi Power, Siemens and others. A 40MW first-off commercial plant is planned and based on published information the plants that competitors have built are (at similar scales) ~55–60% efficient and ~60% dearer than our 68–70% efficient plants.

Projects using any of our technologies are eligible for approval as Projects of Common Interest in the 35 European countries of ENTSO-E, giving access to the multi-billion Euro Connecting Europe Facility and ECB funding for energy, and assistance with permits: one has already been approved. This shows that our technology is important infrastructure at a continental scale.

Our plants deliver:

- balancing services,

- arbitrage (responding fast to grid needs),

- real inertia,

- reactive power/load,

- voltage/frequency control,

- grid operability,

- leakage current protection and similar services,

- grid operations simplification,

- restoration services,

- lower costs,

- avoidance of grid reinforcement costs / constraint reduction.

All 24/7 — and Black Start.

Our plants are much cheaper and more efficient (lifetime average, grid-to-grid) than batteries, with 5X their plant life, and each can concurrently deliver a range of services that would require 4–6 same-sized batteries.