Grid connected batteries are used for many grid services that would be much better and more cheaply delivered by large-scale long-duration storage, for four reasons:

- Battery cost is higher,

- Battery efficiency is lower,

- Dedicated batteries need to be built to deliver each of many services, and

- The services that they can deliver are often inferior.

We will consider what batteries are being built to deliver, service by service.

Comparing Energy Storage: Batteries v. CAES

Because the manufacturers of each technology naturally emphasise their strengths and gloss over their weaknesses in order to present them in the best possible light, it is very difficult indeed to compare different types of energy storage. Please see this brief guide to help compare them.

Balancing Services

Balancing services need to be delivered at capacities at least half of the capacity of a renewable generation farm. As many of these are large, the storage required is large. As batteries scale up, they have few (if any) efficiencies of scale, and if built in a single building its cooling costs multiply with size; whereas the larger a CAES plant is, the less it costs per MW in both capital and operational costs.

Balancing services also need to be delivered for the duration of expected non-generation. This ranges from hours (e.g. evening peak and overnight, for solar in a location with excellent insolation) to days or even weeks (caused by weather patterns that extend low-generation periods, e.g. the fortnight-long kalte Dunkelflaute in most of Western Europe – not just Germany). Doubling a battery’s duration increases its capital cost by ~75-85%; doubling that of Green CAES TM increases it by ~30%; for Hydrogen CAES TM it’s ~15%.

Stability Services

Stability services are based on inertia, which provides the angular momentum required to ride through faults and reduce the Rate of Change of Frequency (RoCoF) which causes damage to equipment and which trips systems. There are a variety of such services such as inertia itself, phase-locked loops, voltage control and frequency control. However, using batteries to do so has a number of constraints because batteries are asynchronous, that is, they operate on direct current. This is a simple explanation of the difference between synchronous and asynchronous generation and its consequences. Examples of such issues include:

- Each of these must be delivered by a different battery, whereas inertial plant delivers all of them together.

- The battery to deliver each must be dedicated to the task, whereas inertial plant delivers it in the course of normal operations – usually as a by-product.

- Although batteries can deliver 10x the digital inertia of a power station of the same capacity, that difference vanishes with suitably configured CAES.

- Synthetic inertia needs an external trigger; real inertia is always on.

- Synthetic inertia is essentially a very fast response time. Any response time whatsoever is a delay, which allows RoCoF events (commonly known as spikes on the mains) to get through. Real inertia is always-on, therefore has no delay, and so prevents the spike getting through. So although synthetic inertia is great for recovery from failures, only real inertia can prevent the failure in the first place. This was discussed extensively in relation to the UK blackouts of 9th August 2019.

Reactive Power and Load

People generally refer to “active power” simply as power, because that is what provides the work done by the electricity. Reactive power is slightly different: it’s like the “push” that gets the active power round the grid. A more detailed layman’s explanation is here.

Synchronous (i.e. naturally inertial, i.e. from large rotating machines) generation delivers both active and reactive power; asynchronous machines don’t. There are trade-offs between active and reactive power; at low levels (say, up to 20% reactive) synchronous machines do not lose a proportionate amount of active power to produce reactive; whereas for asynchronous machines it’s a 1:1 conversion, that is, every MW of reactive power (known as MVAr) costs one MW of active power output. Therefore to deliver reactive power requires dedicated battery capacity, whereas it’s a by-product of inertial storage such as CAES. And Storelectric’s CAES can be configured to deliver at least 6x the reactive power of an equivalent-capacity power station.

Rotating machinery that consumes power is the reverse of this: it provides reactive load. Reactive power and load need to be balanced, leading to a requirement sometimes to increase the reactive load on the system. Batteries cannot consume reactive load unless a dedicated plant is kept un-charged for the purpose. Inertial generation can turn down the reactive element of their output. Synchronous condensers are rotating machines that can provide reactive power and load without active power and minimal active load; Storelectric’s CAES can all be configured to operate also as synchronous condensers, cheaply and without consuming other capacity.

Black Start

Delivering Black Start with batteries requires dedicated batteries that must be kept fully charged and so has no other revenue streams to offset its cost. Hydrogen CAESTM needs no capacity reservation. A hybrid version of Green CAESTM also has a spare capability to double its duration in time of extreme need (albeit at reduced efficiency), and therefore does not need to reserve its normal operating capacity. This makes battery powered Black Start a very expensive option.

Batteries also struggle to start up other equipment and neighbouring parts of the grid owing to their lack of natural inertia; and they are intrinsically unable to start up higher-voltage parts of the grid. This is discussed more extensively here.

Efficiency and Life

Battery life is 8-10 years depending on the load case = duty cycles: heavier use consumes battery life fast. CAES plant life is 40-60 years with mid-life overhaul: the mid-life overhaul for Huntorf was 27 years, and that for McIntosh 29 years.

The efficiency of batteries is nearly always quoted gross, i.e. an internal efficiency only. Storelectric always quotes net efficiency, i.e. grid-to-grid. The main differences are power conversion (AC-DC and back again, which impose losses of 6-12% on day 1) and ancillary loads such as cooling (on day 1, ranging from 5-10% in cooler temperate climates, to 30% or more in hot desert conditions which are the best locations for storage combined with solar). There are many other sources of inefficiency too, as detailed in the tests by PNNL (Pacific Northwest National Laboratory in America).

Then there is aging. By the end of life, the inefficiencies are triple those on day 1. So is the heat emission and therefore cooling requirement. In contrast, CAES barely deteriorates (1-2%) if well maintained.

Therefore the lifetime average whole-cycle efficiency of batteries, claimed to be 85-92%, is actually 50-62%. The whole-cycle efficiency of Green CAES TM is 68-70% at scale (dropping to 63.5% at 40MW); for Hydrogen CAES TM it is 55-62% depending on size.

Multi-Tasking Technology

In considering different storage technologies, it is important to determine the number of services that the storage can deliver concurrently, using the same resources (i.e. not sub-dividing the plant’s output or storage capacity), e.g. one of Storelectric’s plants can deliver concurrently a range of services that require many same-sized batteries:

- Balancing services and arbitrage (based on power and duration);

- Ancillary services (based on speed of response);

- Inertial services (based on inertia, and including related services, such as phase-locked loops) –

- Distinguish between real and synthetic inertia, the former being best for preventing failures and the latter for recovering from them, as shown here;

- Reactive power and load;

- Voltage and frequency regulation;

- Black start (without having to reserve capacity, which some configurations of Storelectric’s CAES can achieve) –

- Distributed batteries just cannot do the job;

- Other services, e.g. constraint management, curtailment avoidance.

Summary of services: batteries v. CAES

| Services | Batteries | CAES |

| Balancing – Scale | Doubling size increases price by ~85%, often more | Doubling size increases price by ~50-70% |

| Balancing – Duration | Doubling duration increases price by ~75-85% | Doubling increases by:

|

| Stability – Inertia | Needs a dedicated plantNeeds external trigger

Synthetic inertia (fault recovery, not prevention) |

By-product of other output; 24/7 in synchronous condenser modeReal inertia (always-on, fault prevention) |

| Stability – Voltage and Frequency Regulation | Needs a dedicated plantNeeds external trigger

Fault recovery, not prevention |

By-product of other output;24/7 in synchronous condenser mode

Always-on Fault prevention |

| Reactive Power | Needs a dedicated plant | Minor load on a plant used for other purposes |

| Reactive Load | Needs a dedicated plant | Minor load on a plant used for other purposes |

| Black Start | Needs a dedicated plantShort duration

Little capability to start other plant or neighbouring grid |

Deliver with plants used for other purposesLonger-duration

Inertia enables starting of other plant & grid sections |

| Plant Life | 8-10 years | 40-60 years |

| Efficiency (whole cycle, whole life average) | 50-74% | Green CAESTM: 63.5-70%H2 CAESTM: ~ 55-62% |

Salami Slicing: Levelised Cost of Storage

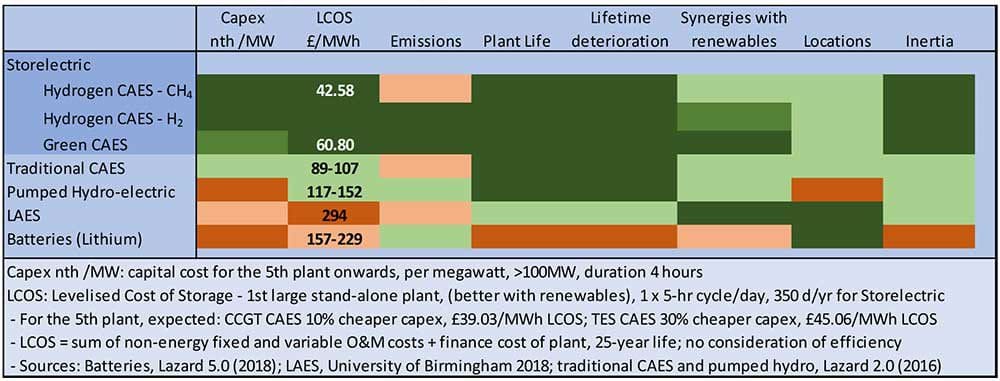

The grossly inefficient, costly and inadequate purchasing of such services from batteries is a well-predicted direct consequence of salami-slicing services. Yet even with all these advantages, the Levelised Cost of Storage of Storelectric’s CAES is lower than that of any other electricity storage technology of similar scale and duration:

Highly Affected by Environmental Temperature

Battery performance and life are very severely affected by the temperature of the environment, with both high and low temperatures greatly reducing both. This means that they need large ancillary loads for both heating and (mainly) cooling to operate year-round in most climates. Evidently these costs are location-specific, though already high for cool and temperate climates.

This tends not to be noticed in domestic and commercial scale batteries which are small enough for convection to work, and many are located within temperature-controlled buildings so the costs of heating and cooling the battery are hidden in the building’s heating and cooling costs. Grid connected batteries, on the other hand, are stand-alone and so require dedicated ancillary systems whose costs are more easily measured.

Shortage of Lithium

There are indeed other battery chemistries than lithium-based ones, but they are a small minority, have little traction and receive a tiny fraction of the investment as lithium. So the availability of lithium is critical to strategies based around batteries enabling the energy transition of transportation (EVs = Electric Vehicles), electricity systems (grid-connected batteries and V2G = Vehicle-to-Grid storage) and portable devices, the three principal applications for batteries.

There is sufficient recoverable lithium in the world to power only 77% of vehicles by 2080, ignoring any use of lithium for the electricity sector (which uses three time as much energy as transportation, including gas as it will be replaced by both P2G [Power to Gas, including electrolysis of water to produce hydrogen] and electrification), portable devices and other uses. This ignores electricity systems and portable devices.

If the 40-60 gigafactories currently planned world-wide are built, they would exhaust the lithium deposits in all current and under-development fields in 2-10 years according to figures from The Economist:

| Vehicles, 2016 | 25 GWh | 750,000 vehicles |

Mid-range projections:

|

15,500 GWh5,000 GWh3,000 GWh | 150,000,000 vehicles465,000,000 vehicles90,000,000 vehicles |

Total lithium, 2016

|

180,000111,600,00036,000,00021,600,000 | tonnes in one year, all usestonnes in one year, just for vehiclestonnes in one year, just for vehiclestonnes in one year, just for vehicles |

| Total available lithium in planet | 210,000,000 | tonnes |

| Years’ output: 2040 Bloomberg | 1.9 years | just for vehicles |

Plans for the electricity sector require similar amounts for grid-connected batteries, which domestic batteries may double. And then the global growth of portable devices and fixed installations of battery devices (e.g. wall-mounted controllers and sensors) need adding. There is further discussion on pages 22-24 of this analysis.

Exploding and Burning Batteries